- Break through! A brand-new revolution in conversion rate SO2 measurement! The conversion rate SO? gas chromatograph (Micro-GC) has been successfully tested on-site in sulfuric acid enterprises in multiple provinces

Recently, a new type of SO? gas chromatograph developed by our team has completed on-site testing at several sulfuric acid production plants. This marks a significant breakthrough for China's sulfuric acid industry, transitioning from years of manual conversion rate measurement to intelligent instrument-based analysis. The instrument, with "precision, speed, and safety" as its core features, successfully addresses numerous pain points of traditional measurement methods, injecting new momentum into the industry's high-quality development.

Traditional methods are limited, and the industry is calling for new solutions

The sulfuric acid industry has long used the iodometric method for measuring SO? content. This method is not only cumbersome and time-consuming but also involves the toxicity of iodine solution and the severe environmental pollution caused by high-concentration SO? emissions during measurement, posing health risks to operators. Measurement results are often biased due to human factors, making it difficult to reflect the real-time conversion rate during production. Therefore, the industry urgently needs a new solution that ensures both personnel health and safety, as well as accurate and rapid measurement.

Innovation: With the advent of conversion rate chromatography analyzers, conversion rate measurement is no longer a difficult problem

Innovation transforms the measurement of conversion rate in sulfuric acid plants (SO?), making it accurate, fast, and simple through chromatographic analysis technology, supporting high-quality green production and intelligent analysis in the sulfuric acid industry.

Main Functions

·Segmented Conversion Rate Measurement

·Total Conversion Rate Measurement

·Tail Gas Emission Monitoring

·Catalyst Activity Assessment

·Heat Exchanger Leak Detection

·Measurement Range

SO? concentration: 10ppm~100%

O? concentration: 10ppm~100%

H?S concentration: 10ppm~100%

Repeatability (RSD) better than 0.2%

Measurement Time: 50 seconds

The SCA-400 Conversion Rate Chromatographic Analyzer utilizes a compact, lightweight rapid chromatography function, enabling precise and fast analysis of SO? concentration in sulfuric acid production environments, calculating the conversion rate, and identifying issues like heat exchanger leaks and catalyst short circuits. Based on mature micro gas chromatography (GC) technology, it meets the most challenging analytical requirements for conversion rate (SO?) in the current sulfuric acid industry's lean production with excellent sensitivity (10ppm) and high repeatability (±0.02%). It represents a new phase for the sulfuric acid industry, moving from manual analysis to automated instrument analysis. It is the perfect combination of powerful analytical capability and ease of use, seamlessly integrating the dual demands of detection precision and response speed. The SCA-400 achieves seamless integration of online SO? concentration monitoring and real-time conversion rate calculation. It also possesses the portable analysis capability for offline multi-unit sulfuric acid plants, suitable for measuring multiple units and handling sudden operational conditions, significantly improving inspection flexibility and emergency response efficiency.

Accurate and reliable

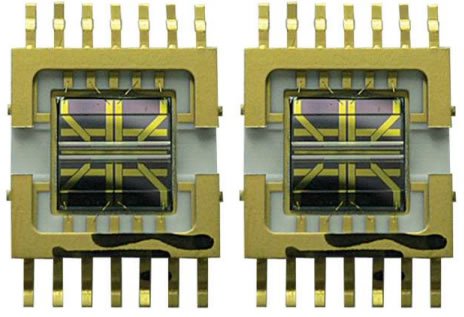

The Conversion Rate Chromatographic Analyzer is equipped with a Micro-Electro-Mechanical Systems (MEMS) based micro Thermal Conductivity Detector (µTCD), with a detection limit reaching 10ppm, offering a sensitivity 10 times higher than conventional TCD. It incorporates high-temperature programmed temperature vaporization chromatographic column technology, effectively improving separation capability and sensitivity for later eluting peaks, providing more sensitive and reliable analysis for highly adsorbable SO?.

MEMS μTCD can detect SO2 concentrations as low as 10 PPM

Rapid measurement

With one-click start, the instrument automatically completes the entire process of sampling and analysis. The SO? analysis speed is increased by 95% compared to the iodometric method. Analyzing the segmented conversion rate for a single set of 3+2 sulfuric acid plant requires only 5 minutes to complete the full parameter output of SO? concentration and conversion rate. For handling sudden operational conditions, a single-point analysis requires only 50 seconds to complete SO? concentration analysis. Furthermore, no manual intervention is needed during the measurement process, as the instrument performs automatic analysis, greatly enhancing analysis efficiency and data reliability.

The conversion rate spectrum clearly shows the peak shapes and retention times of the inlet and outlet SO?

Easy to use

The operation interface is intuitive and concise, allowing users to get started quickly without professional chromatographic knowledge. Analysis can be run from the front panel or from a wirelessly connected computer. The web-based chromatography software is independent of the computer operating system. Equipped with conversion rate calculation software, it can automatically calculate the conversion rate in real-time based on the inlet and outlet SO? concentrations, generate trend curves and historical data reports. It includes a built-in converter intelligent health diagnosis system, capable of real-time assessment of catalyst activity changes and heat exchanger operating status.

Instrument Features

· SO? measurement for conversion rate is pollution-free throughout the process, effectively protecting the environment and personnel health.

· Fast measurement, completing plant conversion rate and leak detection in 1~5 minutes.

· Built-in automatic calibration function ensures long-term operational stability.

· Patented SO? filtration technology effectively removes SO? components from the sample gas, preventing corrosion and adsorption interference on the chromatographic column and detector.

The on-site actual test was successful, and the user recognition continued to rise

Since mid-October, the team has traveled to enterprises in Chongqing, Hubei, and other locations to conduct on-site tests. During the testing process, the instrument performed stably and operated smoothly, with seamless connection from preheating, calibration, sampling, to analysis. Staff used specialized syringes to collect gas samples on-site, combined with alkali scrubbing bottles for tail gas treatment, fully implementing the concept of green measurement.

Test results showed that the instrument not only measures quickly and provides accurate data but also significantly reduces occupational health risks for operators, receiving unanimous praise from enterprise technical personnel. "It used to take most of the day to measure SO?, now we can get results in half an hour, without worrying about toxicity and pollution," commented one on-site engineer.

Drive industry upgrading, dedication leads to professionalism

The successful promotion of this Conversion Rate Gas Chromatograph is a concrete reflection of the R&D team's adherence to the original intention of "focusing on the sulfuric acid industry and solving measurement challenges." This equipment is not just an analytical instrument but an important tool for the intelligent and safe transformation of sulfuric acid production.

In the future, as this technology is promoted and applied in more sulfuric acid enterprises nationwide, SO? measurement will truly enter a new stage of precision, speed, and safety, providing solid support for the green development and efficiency improvement of China's sulfuric acid industry.

The following are the on-site measurement data of a certain sulfuric acid:

The measured data results and calculated total conversion rate at the sulfuric acid site are as follows:

.jpg)